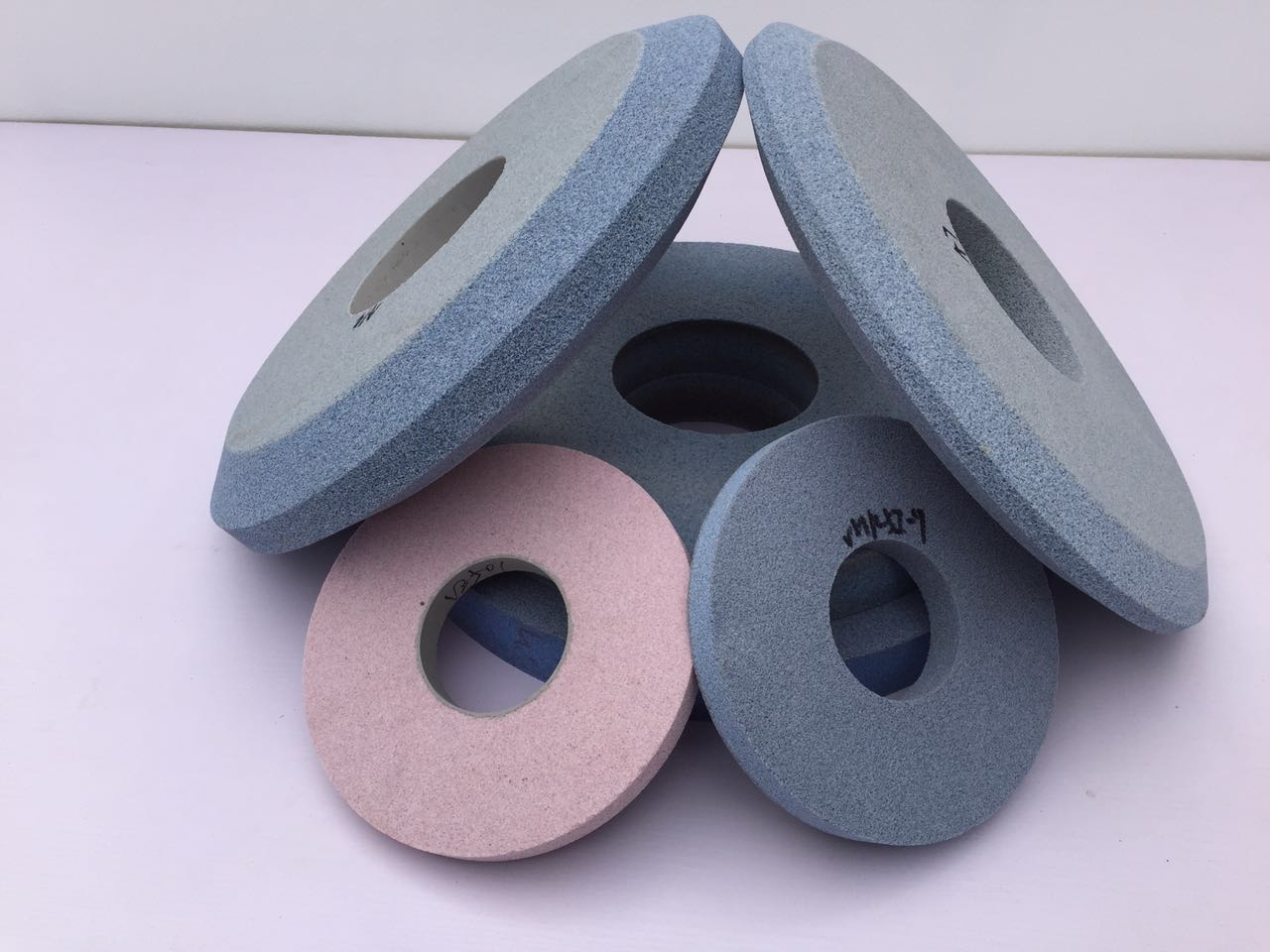

高速蜗杆磨砂轮 High-Speed Worm Gear Grinding Wheels

High-Speed Worm Gear Grinding Wheels

高速蜗杆磨砂轮

性能简介

公司研发的数控高速蜗杆磨齿机砂轮,其材质主要有5GW(等效于5SG)、7ZEI等同于国外品牌93A)、10Z(等同于国外品牌80N)及公司特有材质5EZ。

·5GW系列其特点是磨削锋利、抗粘附防烧伤,特别适合于高合金类齿轮的磨削加工,亦适合于通用齿轮。·7ZE系列主要适用莱斯豪尔磨齿机常规产品的磨削加工。·10Z系列主要适用于KAPPA磨齿机常规产品的磨削加工。公司特有材质是应客户特殊要求订制。常用砂轮参数为80#J8V50~80m/s

产品规格型号及适用机床

产品代码 砂轮规格型号 砂轮参数 适用机床

R 275125160 80#~120~J8V80m/s 莱斯豪尔等

R 275*160*160 80#~120~J8V80m/s 莱斯豪尔等

R 300*125*160 80#~120~J8V80m/s 莱斯豪尔、秦川、南二机等

R 300*145*160 80#~120~J8V80m/s 莱斯豪尔、秦川、南二机等

K 280*160*115 80#~120-J8V50-72m/s 卡普等

L 240*230*110 80#~120~J8V50~63m/s 立博海尔等

G 240*125*120 80#~120~J8V50~63m/s 格里森等

195*200*90 80#~120~J8V50~63m/s 桑普塔斯力等

订货注意事项

磨加工常规材质常规精度齿轮M≥2的选用80#砂轮。

磨加工常规材质常规精度齿轮1.25≤M<2的选用100#砂轮。磨加工常规材质常规精度齿轮M<1.25的选用120#砂轮。特殊需要的另行设计制作。

常规产品可在订单产生后10个工作日内发货,所有特殊定制产品形成稳定供需关系后亦可在10个工作日内发货,请根据生产计划合理安排订货以减少资金占用。

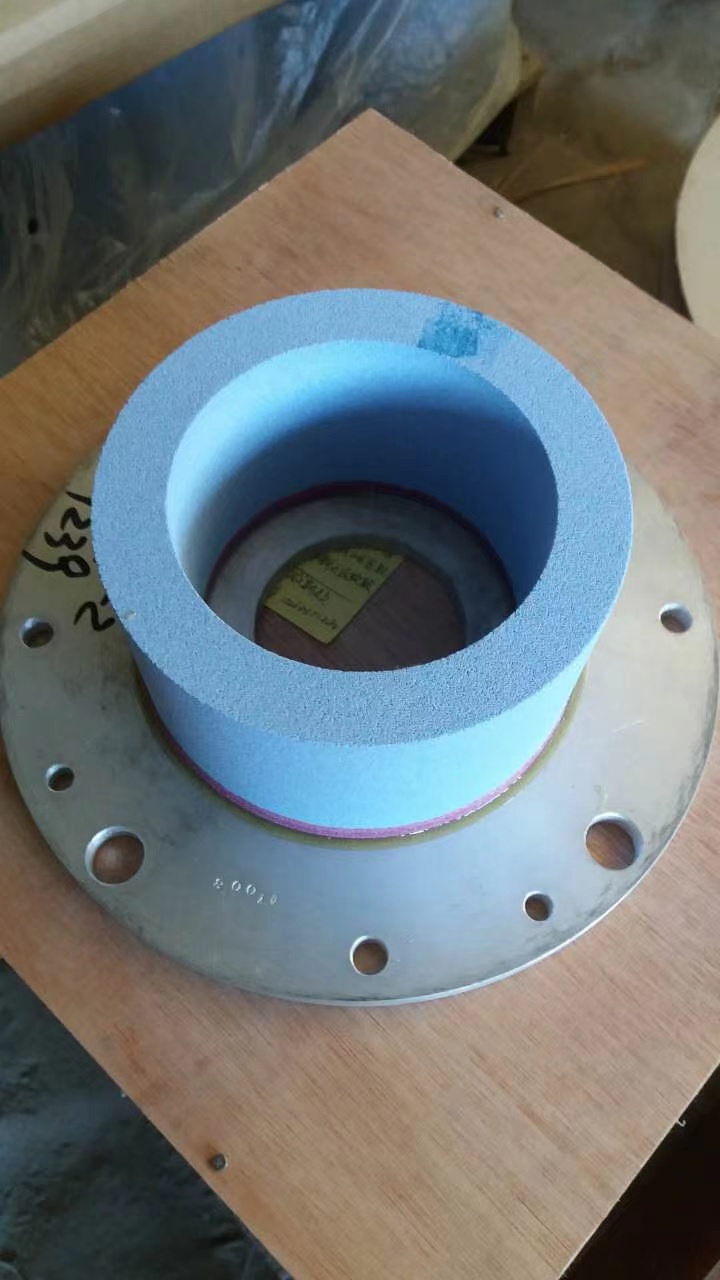

由于此类砂轮使用速度高、吃刀量大(负荷重),请严格按设备厂家要求选用砂轮装卡,卡紧减震垫,以确保使用安全及使用效果。

由于此类砂轮使用时的特殊修形形状,请选择开好模数槽型的成品砂轮,以确保使用安全性和良好的使用效果。

High-Speed Worm Gear Grinding Wheels

Performance Introduction

The grinding wheels for CNC high-speed worm gear grinding machines developed by our company are primarily made of the following materials: 5GW (equivalent to 5SG), 7ZE (equivalent to the foreign brand 93A), 10Z (equivalent to the foreign brand 80N), and our proprietary material 5EZ. The 5GW series is characterized by sharp grinding performance, anti-adhesion, and burn resistance, making it particularly suitable for grinding high-alloy gears as well as general-purpose gears. The 7ZE series is mainly used for grinding standard products on Reischauer gear grinding machines. The 10Z series is primarily suitable for grinding standard products on KAPP gear grinding machines. Our proprietary material 5EZ is customized to meet specific customer requirements. Common grinding wheel parameters are 80# J 8V 50–80 m/s.

Specifications:

Code | Size (mm) | Parameters | Applicable Machines |

R | 275×125×160 | 80#–120# J8V 80m/s | Reishauer |

K | 280×160×115 | 80#–120# J8V 50–72m/s | KAPP |

G | 240×125×120 | 80#–120# J8V 50–63m/s | Gleason |

Ordering Guidelines

For grinding conventional materials and standard-precision gears:

Gears with module (M) ≥ 2: Use 80# grinding wheels.

Gears with module (M) 1.25 ≤ M < 2: Use 100# grinding wheels.

Gears with module (M) < 1.25: Use 120# grinding wheels.

Custom designs are available for special requirements.

Standard products will be shipped within 10 working days after order.

Customized products can also be shipped within 10 working days once a stable supply relationship is established. Plan orders according to production schedules to minimize inventory costs.

Safety and Performance Notes:

Due to the high operating speeds and heavy cutting loads of these grinding wheels, strictly adhere to the manufacturer’s specifications for wheel mounting. Ensure secure clamping with vibration-damping pads to guarantee safety and optimal performance.

To ensure safety and effectiveness, always use pre-machined grinding wheels with modulus-specific grooves tailored to your application.

在线订购

栏目导航

联系我们

联系人: 张先生 Kevin

电话: 0086-17778938919

微信:0086-17778938919

地址: 中国陕西省西安市朱雀路78号 No.78, Zhuque Road, Xi'an, China, 710061